Hubei Heqiang Machinery Development Limited by Share Ltd was established in December of 2000. The company is

located in Ezhou of Hubei province, next to Wuhan

city, with an area of 40,000 square meters and 120

employees. Since its establishment, Hubei Heqiang is

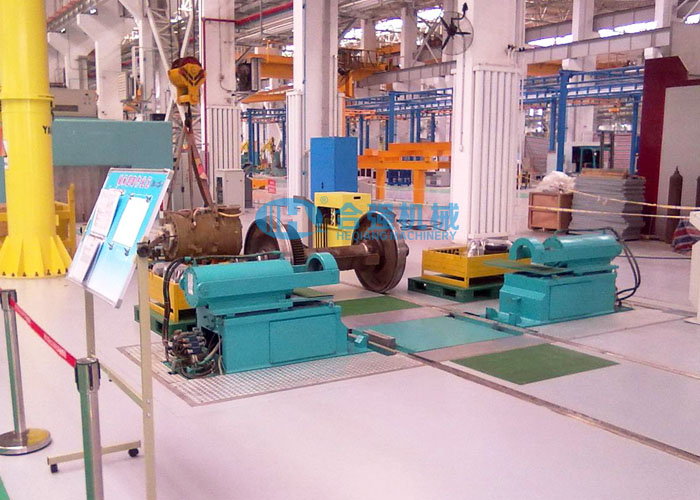

mainly engaged in R&D, design, manufacture, sales, maintenance

and service of railway workshop equipment and forging

equipment. After more than 20 years' rapid development, Hubei

Heqiang has already grown into one of the leading manufacturers of

raiway workshop equipment and forging equipment in the market.

Hubei Heqiang is a High-Tech enterprise and owns more than 130

patents, including 11 invention patents and 14 software

copyrights. The company always adheres to the quality policy

of "Innovative design, Strict control, Elaborate assembly and

Customer satisfaction", and currently has more than 150 sets of

equipment for metal machining, welding and test. It has formed an

unique system of equipment configuration and quality control

and got the certificates of ISO9001:2015,

ISO14001:2015 and ISO45001:2018. During business operation

process, Hubei Heqiang always adheres to the implementation of

the industry's highest management standards, continuous improvement

of the work, continuous improvement of products and service, to

reach the maximum pursuit of customer satisfaction.

The company is committed to build Hubei Heqiang into the most

advanced manufacturer of railway workshop equipment and to

provide better products and service for all the

related industries.

The products have been exported to Mauritania, Guinea, Kenya,

Algeria, Serbia, Poland, Russia, Azerbaijan, Uzbekistan, Mongolia,

Saudi Arabia, Iran, Myanma, Vietnam, Malaysia, Singapore,

Indonesia, Peru, Chile, Suriname, Colombia, Mexico, Canada, etc.